The Environmental Impact of Sneaker Production: Sustainable Alternatives

The Environmental Impact of Sneaker Production: Sustainable Alternatives to Consider explores the environmental consequences of sneaker manufacturing and highlights various eco-friendly materials and production methods that can minimize the industry’s carbon footprint.

The quest for the perfect pair of sneakers often overlooks a critical aspect: its impact on our planet. Let’s explore the environmental impact of sneaker production: sustainable alternatives to consider for a more eco-conscious approach.

Understanding the Environmental Footprint of Sneaker Production

The sneaker industry, with its global reach and massive production volumes, significantly contributes to environmental degradation. Understanding the different aspects of this impact is the first step towards adopting more sustainable alternatives.

Raw Material Extraction and Processing

The journey of a sneaker begins with the extraction of raw materials, many of which are sourced unsustainably. Cotton farming uses significant amounts of water and pesticides, while rubber plantations contribute to deforestation.

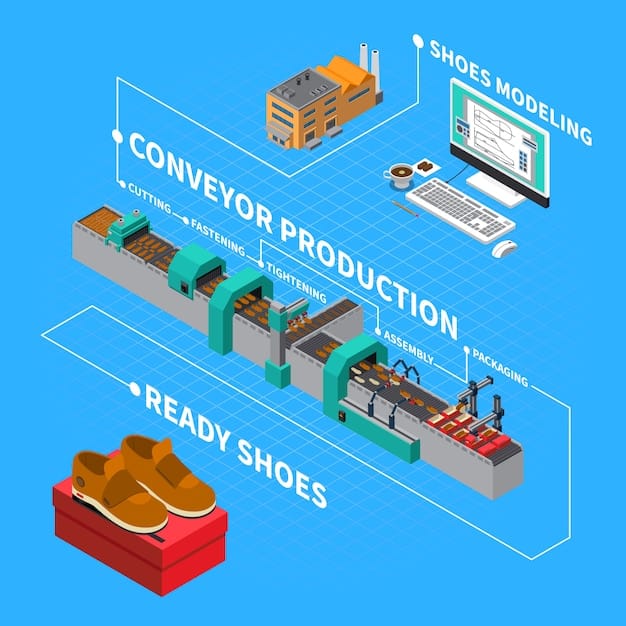

Manufacturing Processes and Waste Generation

The manufacturing process involves various energy-intensive steps, from cutting and stitching materials to molding soles. These processes generate considerable waste, including scraps of fabric, rubber, and plastic.

- Energy Consumption: Sneaker factories often rely on fossil fuels, contributing to greenhouse gas emissions.

- Water Usage: Dyeing and washing processes consume large quantities of water, often releasing polluted wastewater into the environment.

- Chemical Use: The use of adhesives, dyes, and other chemicals can lead to pollution and health hazards for workers.

Moreover, the short lifespan of many sneakers adds to the problem. Fast fashion trends encourage frequent replacements, leading to more waste accumulating in landfills.

In conclusion, sneaker production’s environmental footprint is broad, encompassing resource depletion, pollution, and waste accumulation. Recognizing these impacts is crucial for promoting a shift towards more sustainable practices in the industry.

The Role of Materials in Sustainable Sneaker Design

Selecting the right materials is key to creating eco-friendly sneakers. Sustainable materials can significantly reduce environmental impact and promote responsible sourcing.

Recycled Materials: Giving Waste a Second Life

Using recycled materials, such as recycled plastics and rubber, can divert waste from landfills and reduce the need for virgin resources. Many brands are now incorporating recycled materials into their sneaker designs.

Organic and Natural Fibers: Environmentally-Friendly Alternatives

Organic cotton, hemp, and other natural fibers are grown without harmful pesticides and require less water than conventional cotton, offering a more sustainable option for uppers and linings.

- Tencel: This lyocell fiber is made from sustainably sourced wood pulp, offering a soft and durable alternative to conventional textiles.

- Piñatex: Made from pineapple leaf fibers, Piñatex is a vegan leather alternative that reduces waste and supports agricultural communities.

- Cork: A renewable and biodegradable material, cork can be used for soles and other components, offering a sustainable alternative to traditional rubber.

Innovative materials like mycelium, derived from mushrooms, are also gaining traction. Mycelium can be grown into various shapes and used as cushioning or structural components.

In summary, sustainable sneaker design relies on eco-friendly materials that minimize environmental harm. By choosing recycled, organic, and innovative materials, manufacturers can create sneakers that are both stylish and sustainable.

Eco-Friendly Manufacturing Processes for Sneakers

Beyond material selection, implementing eco-friendly manufacturing processes is essential to reduce the environmental impact of sneaker production. These processes focus on minimizing waste, conserving energy, and reducing pollution.

Waterless Dyeing Techniques

Traditional dyeing methods consume large amounts of water and chemicals. Waterless dyeing techniques, such as air dyeing and supercritical CO2 dyeing, eliminate water usage and reduce chemical waste.

3D Printing and On-Demand Production

3D printing allows for on-demand production, reducing waste by creating only what is needed. This technology also enables customized designs and more efficient use of materials.

Another crucial aspect is reducing transportation emissions by sourcing materials locally and optimizing supply chains, which minimizes the carbon footprint associated with shipping and logistics.

In conclusion, eco-friendly manufacturing processes are vital for reducing the environmental impact of sneaker production. By adopting waterless dyeing, 3D printing, and efficient supply chain management, manufacturers can create sneakers more sustainably.

Brands Leading the Way in Sustainable Sneaker Production

Several brands are pioneering sustainable practices in the sneaker industry, demonstrating that it is possible to create stylish and eco-friendly footwear. These brands are setting new standards and inspiring others to follow suit.

Adidas: Incorporating Recycled Materials and Innovation

Adidas has made significant strides in sustainability through partnerships and innovative technologies. Their collaboration with Parley for the Oceans has resulted in sneakers made from recycled ocean plastic.

Nike: Sustainable Materials and Circular Design

Nike has committed to using sustainable materials and designing products for circularity. Their Flyknit technology reduces material waste and their Refurbished program extends the lifespan of used sneakers.

- Allbirds: Known for their use of natural and sustainable materials like merino wool and eucalyptus tree fiber, Allbirds is committed to reducing their carbon footprint.

- Veja: This French brand uses organic cotton, wild rubber from the Amazon, and recycled materials to create stylish and sustainable sneakers.

- Rothy’s: Specializing in shoes made from recycled plastic bottles, Rothy’s combines sustainability with fashion and comfort.

These brands are also focusing on transparency, providing consumers with information about their supply chains and environmental impact. This builds trust and encourages informed purchasing decisions.

In summary, several brands are leading the way in sustainable sneaker production, showcasing innovative materials, eco-friendly processes, and a commitment to transparency. Their efforts are inspiring change and demonstrating that sustainability can be a core part of the sneaker industry.

Consumer Choices: How to Support Sustainable Sneaker Brands

As consumers, we have the power to drive change by supporting sustainable sneaker brands and making informed purchasing decisions. Our choices can encourage the industry to adopt more eco-friendly practices.

Researching Brands and Materials

Before buying a pair of sneakers, research brands and their sustainability initiatives. Look for certifications like the Global Organic Textile Standard (GOTS) and consider the materials used in the construction.

Extending the Lifespan of Your Sneakers

Proper care and maintenance can extend the lifespan of your sneakers, reducing the need for frequent replacements. Repairing and repurposing old sneakers can also minimize waste.

Supporting companies that offer repair services or take-back programs ensures that your sneakers are properly recycled or repurposed at the end of their life. This prevents them from ending up in landfills.

In conclusion, consumer choices play a crucial role in supporting sustainable sneaker brands. By researching brands, extending the lifespan of sneakers, and participating in recycling programs, we can collectively promote a more sustainable sneaker industry.

The Future of Sustainable Sneaker Production

The future of sneaker production lies in continuous innovation, collaboration, and a commitment to environmental responsibility. Advancements in technology and materials will drive further improvements in sustainability.

Technological Innovations for Enhanced Sustainability

Emerging technologies like bio-based materials, advanced recycling techniques, and closed-loop manufacturing systems hold great promise for reducing the environmental impact of sneaker production.

Collaboration and Industry-Wide Standards

Collaboration between brands, suppliers, and researchers is essential to develop and implement industry-wide sustainability standards. Standardizing environmental metrics and certifications can help consumers make informed choices.

- Government Regulations: Policies and regulations that incentivize sustainable practices can drive broader adoption of eco-friendly materials and processes.

- Consumer Awareness: Educating consumers about the environmental impact of their choices and promoting sustainable alternatives is crucial for driving demand.

- Investment in Research and Development: Investing in research and development of innovative materials and technologies can accelerate the transition to a more sustainable sneaker industry.

The growing awareness of environmental issues and the increasing demand for sustainable products are driving positive change in the sneaker industry. As consumers become more conscious of their choices, brands are compelled to adopt more sustainable practices to remain competitive.

In summary, the future of sustainable sneaker production depends on technological innovations, industry collaboration, and consumer awareness. By embracing these elements, the sneaker industry can minimize its environmental impact and contribute to a more sustainable future.

| Key Point | Brief Description |

|---|---|

| 🌱 Sustainable Materials | Use of recycled, organic, and innovative materials to reduce environmental impact. |

| 💧 Waterless Dyeing | Techniques like air dyeing that eliminate water usage and reduce chemical waste. |

| ♻️ Recycling Programs | Supporting take-back programs to ensure proper recycling and repurposing of old sneakers. |

| 🤝 Brand Transparency | Choosing brands that are transparent about their supply chains and environmental impact. |

FAQ

▼

Sneaker production involves resource extraction, energy-intensive manufacturing, and waste generation. Materials such as cotton and rubber contribute to deforestation and pollution, while the manufacturing process adds to greenhouse gas emissions.

▼

Sustainable materials include recycled plastics, organic cotton, hemp, Tencel, Piñatex, and cork. These materials reduce the need for virgin resources and minimize the environmental impact associated with raw material extraction.

▼

Waterless dyeing techniques, such as air dyeing and supercritical CO2 dyeing, eliminate water usage and reduce chemical waste. This greatly lowers the environmental footprint compared to traditional dyeing methods.

▼

Brands like Adidas, Nike, Allbirds, Veja, and Rothy’s are leading the way by using sustainable materials, implementing eco-friendly manufacturing processes, and promoting transparency in their supply chains.

▼

Consumers can support by researching brands, choosing products made with sustainable materials, extending the lifespan of sneakers, and participating in recycling programs. Informed purchasing decisions can drive positive change.

Conclusion

In conclusion, addressing the environmental impact of sneaker production requires a multifaceted approach, including the use of sustainable materials, eco-friendly manufacturing processes, brand transparency, and conscious consumer choices. By embracing these strategies, the sneaker industry can move towards a more sustainable and responsible future.